Cooling towers SK-400, SK-1200

Engineering. Cooling towers SK-400, SK-1200

- large single productivity, which can reduce occupied area on the premises;

- a small length of water supply lines;

- possibility of use in harsh climatic conditions;

- increased, in comparison with the tower cooling towers, resistance to strong winds;

- frost resistance, thanks to the ability to turn off fans to reduce cravings;

- control of cooling capacity by changing the rod;

- easy installation and ease of repair.

|

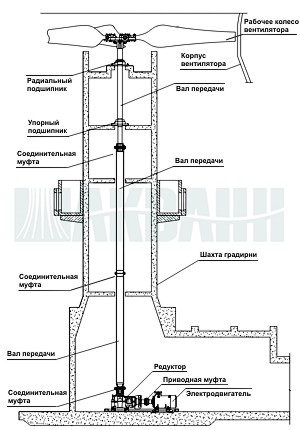

Lower gear drive involves the placement of e/d, and the angular reducer of the type in the engine room under the tower.

Torque is transmitted to the impeller via a system of vertical steel shafts passing through the shaft of the tower.

The layout of the drive equipment is associated with the increased load on the thrust bearing of reducer and steel drive shafts.

|

|

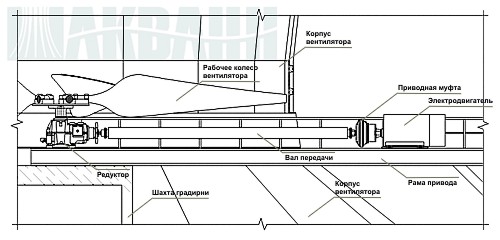

Top gear drive involves the placement of e/d, the transmission shaft and reducer angle-type at the level of the fan impeller on a supporting structure outside the fan casing.

|

- replacement of the driven equipment (e/e, gearbox, drive shafts, transmission couplings);

- replacement of ventilation equipment (impeller, fan stack);

- replacement of water distribution systems (headers, injectors);

- replacement of drift eliminators;

- replacement of cooling fills;

- replacement grounds maintenance / equipment placing;

- the installation process control system (including a separate hermetically sealed unit-box with translation of the operating voltage from 6000 V To 380 V).

|

Parameter |

Unit |

SK-400

|

SK-1200

|

| Volume flow |

m3/h

|

3000 - 4500

|

12000 - 18000

|

| Heat load |

MWt |

42 - 63

|

168 - 252

|

| Diameter of section |

m

|

24

|

36

|

| Тmax inlet water |

oС |

36 - 37 |

36 - 37 |

| Tmin оcooled water |

oС

|

24 - 25

|

24 - 25

|

| Diameter of the fan |

мм

|

10400

|

20000

|

| Drive power |

kWt

|

up to 250

|

up to 800

|

Technologies

Fan impellers WTR

In 2009, the company AKVANN mastered the production of impellers of the fans of the brand of WTR composite materials reinforced with fiberglass. Taking into account the most modern achievements of world leaders in this field, we have designed a line of impellers that are responsive to the needs of the consumer from the point of view of technical, operational and noise characteristics.

Impeller stamps WTR may have a diameter of up to 20000 mm and the number of blades from 3 to 8. Possible to use 3 different variants of the profile of the impeller, as well as several variants of external protective coating: antistatic, antacid/protivosokowoe, self-extinguishing, high temperature/low temperature.

Before installing the cooling tower by a dynamic balancing of the impeller Assembly with the hub in 2 planes according to standard ISO 1940-1-2007. All impellers are provided with the quality certificate of manufacturer, certificate of industrial safety of the Russian Federation. If necessary, the impeller can be manufactured in explosion-proof execution.

The fan stack ADW for cooling towers SK-400, SK-1200

Currently for cooling towers SK-400 AKVANN company has developed and produced the fan casing is made of fiberglass ADW 10400x11140.

The fan stack has a confuser and diffuser parts and is a self-supporting structure with a base diameter - 20 000 mm, height - 15 000 mm, weight of just 11 tonnes. For comparison, metal body with internal supporting structures weigh about 30 tons. The lack of inside self-supporting body of the supporting structures reduces the thermal resistance of the cooling tower to increase cooling.

This housing type is installed on the cooling tower SK-1200.

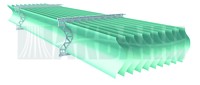

Cooling fills

Is one of the main structural elements of the cooling tower, defining its cooling ability. The cooling fills design must provide sufficient surface area to cool with optimal aerodynamic resistance.

Taken into account and a number of other factors, the durability of the material of the cooling fills in the environment of use, durability, weight, ease of installation and maintenance, as well as the presence in water of suspended solids and corrosive contaminants. The choice of sprinkler is done on the basis of the thermal calculation, taking into account the performance of the material.

Depending on the airflow rate, size of water drifting, the operating environment, used two version of drift eliminators type "wave" with a height of 185 mm slats, and meshed drift eliminators with horizontally oriented tubes.

|

Drift eliminator type "wave"

Drift eliminator of PVC / fiberglass, bonded fastening elements from polypropylene.

Height 185 mm lamella, distance between lamellas 40 / 50 mm.

Nominal drop ablation: 0.001-0.003 % / 0.003-0.004 %. Flow rate 1.0-3.0 m/s.

|

|

Meshed drift eliminators

Drift eliminator polymer horizontal latticed shells with a diameter of 45 mm, placed in 3 layers in parallel to each other. Material: HDPE 273-79, stable carbon.

Height 130 mm. nominal drip ash: 0.04 %. The flow velocity of 2.0-3.0 m/c.

|

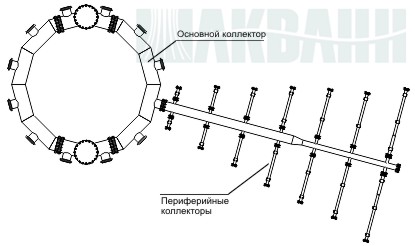

Consists of a main manifold and a peripheral outlet manifold. An important factor in the choice of structural material for the WDS is the corrosion resistance in the operating environment, strength characteristics and weight.

|

Used 2 versions of VRS:

• Main collector – fiberglass, peripheral reservoirs – polyethylene;

• Main collector – fiberglass, peripheral collectors – fiberglass;

On request it is possible production version of the collectors of steel with corrosion-resistant coating.

|

Spray nozzles

Priorities when choosing spray nozzles is the optimal combination of the following parameters: operating point (flow rate – working pressure), corrosion resistance, ease of installation and replacement life.

|

Spray nozzle UPP The diameter of external thread 2“. The range of flow rates is 3.2 m3/h to 10.5 m3/h in the range of operating pressures 0.01-0.04 bar. Average irrigation area of 1 m2. |

Is designed to bring the chemical composition of recycled water in accordance with the technical norms for the correct operation of cooling towers and technological equipment of water circulation circuit.

Significant loss of water by evaporation, particularly in summer operation, cooling towers – up to 3% per hour increase in circulating water concentration of hardness salts. Salt deposits adversely affect the distribution system, the spray nozzles, the corrosiveness of the coolant increases as well.

Effective solution of this problem are demineralisers installation on ion-exchange resins and anticorrosive agents. To prevent the growth of biological microorganisms, the system adds the chemicals-biocides.

Usually the high Flow rate of water in cooling towers SK-400, SK-1200, water treatment system usually are placed in a separate specially equipped room. Also produced mechanical water filtration from the insoluble substances.

Automation

Typically, the selection of the cooling tower, is made for the hottest period of the year - 3 summer months. During this period, the cooling tower is operating at maximum capacity. The rest of the time max laid resource productivity leads to a waste of energy.

The lack of control in the autumn-spring period of operation also leads to disruption of the stability of the cooling water with a "cold" start-up of equipment and, as a consequence, the early wearing of its resources.

To prevent accidents or damage of expensive drive technology, automatic control system of the cooling tower is equipped with necessary systems of monitoring, to track, to warn of malfunctions and, if necessary, to stop the operation of the cooling tower, preventing critical consequences.

Operation of cooling towers in explosive surroundings without the automatic control system is also impossible.

In this regard, we can formulate the main purposes of automation of cooling towers:

- stability of cooling process;

- reducing energy consumption;

- reliable operation in cold operation period;

- safety of equipment and personnel;

- remote monitoring and control;

- reducing the influence of human factor on technological process;

- аutomation of cooling tower SK-400, SK-1200 in the basic version includes a monitoring / control:

- temperature input and output of water,

- the ambient air temperature,

- the vibration of the Fan Assembly,

- frequency speed control of the motor,

- the oil temperature in the gearbox,

- the oil pressure in the gearbox,

- oil contamination in the gearbox,

- heating oil in the gearbox,

- the temperature of bearings and windings of the motor,

- anti-condensation heated of the motor,

- the coolant flow,

- the liquid level in a collecting tank,

- electricity consumption,

- the fluid pressure in the pressure line,

- frequency regulation speed of pumping equipment.

Available integration of local APCS in the complex treatment system of the enterprise protocols of Ethernet or RS-485/422/232.2.

Block transformer substation for cooling towers SK-400, SK-1200

Company AKVANN carries out a full complex of works on reconstruction of cooling towers of the type SK-400 or SK-1200 turnkey.