Forced Draft Cooling Towers

Cooling towers are called sectional, because their individual prefabricated elements are self-contained sections, which are assembled into a single cooling system water cycle. Typical sections of the cooling towers AKVANN at the moment covers quite a wide range of sizes: 6x6, 8х8, 10x10, 10x12, 10x14, 12х12, 12х16, 13.5x13.5, 14x14, 14.8x14.8, 16x12, 16x16 meters with an irrigation area of 36, 64, 100, 120, 140, 144, 192, 182, 194, 219, 192, 256 м2 accordingly. Individual projects are created in the cooling tower the size of the partitions 18х18м, total irrigation which is 324 м2.

Alternatively, the cooling tower SK-400 can be used 2-section cooling tower with the size of the partition 10x14 m and irrigation area of 280 m2.

Sectional cooling tower fan is designed for regions with design temperature not lower - 40оС, design wind pressure of 1.2 kPa, the normative snow load of 3.2 kPa and a seismic intensity of 8 points according to MSK-64 scale.

Cell cooling tower able to meet the increased demand from cooling systems. The use of components made of new materials and the use of modern technology allowed greater exibility in their operation and achieve high performance. So now they have got the greatest application in various branches of domestic industry.

Тypical solution

Basic models of sectional cooling towers AKVANN and characteristics:

|

Type |

Cell size 1,

м |

Number of sections,

psc. |

Water flow rate on section2, м3/h

|

Heat removal,

oС |

The drive power,

kW |

|

6 x 6 |

1 - 5 |

180 - 720 |

до 15 |

25 - 37 |

|

|

8 x 8 |

1 - 5 |

320 - 1280 |

до 15 |

37 - 75 |

|

|

10 x 10 |

1 - 5 |

500 - 2000 |

до 15 |

75 - 160 |

|

|

10 x 12 |

1 - 3 |

600 - 2400 |

до 15 |

90 - 200 |

|

|

10 x 14 |

1 - 3 |

700 - 2800 |

до 15 |

90 - 200 |

|

|

12 x 12 |

1 - 3 |

720 - 2880 |

до 15 |

110 - 200 |

|

|

12 x 16 |

1 - 3 |

960 - 3840 |

до 15 |

110 - 250 |

|

|

13.5 x 13.5 |

1 - 3 |

910 - 3650 |

до 15 |

110 - 250 |

|

|

14 x 14 |

1 - 3 |

980 - 3920 |

до 15 |

132 - 315 |

|

|

AKVA - 219 |

14.8 x 14.8 |

1 - 3 |

1100 - 4400 |

до 15 |

132 - 315 |

|

16 x 12 |

1 - 3 |

960 - 3840 |

до 15 |

110 - 250 |

|

|

16 x 16 |

1 - 3 |

1280 - 5120 |

до 15 |

132 - 355 |

|

|

18 x 18 |

1 - 3 |

1620 - 6480 |

до 15 |

132 - 400 |

1 - the first value is the length of the section from the side air intake window, the second value is the length of the section end;

2 - when calculating the consumption of water, the irrigation density was varied in the range 5-20 м3/(h•м2);

5 - two sections replaces the cooling tower SK-400. Can be installed on an existing water catchment tank cooling tower SC-400.

|

AKVA-ХХХ -T -N |

|

| АKVA | - the brand name of cooling tower AKVANN |

| -ХХХ | - model of cooling tower (square section) |

| -N | - number of sections |

| -T | - drive type: R – reducer gear scheme, T – scheme with low-speed drive. |

Engineering

The maximum difference of cooling water in a section of the fan cooling towers for the summer may be 12-15C.

Thermal calculation of the cooling towers is based on the methodology the research Institute of VODGEO, given the additions to the company AKVANN. The calculation is made for the hottest period of operation of the cooling tower in the securities of atmospheric parameters 95% or 99%. Thus we guarantee that the equipment will provide the intended cooling tower performance cooling even in the summer peak period. To assess the operational capabilities of the cooling tower also carried out the calculation of its operation depends on different factors: water temperature at the input; the ambient temperature (spring and autumn, summer); consumption of water supplied for cooling; relative humidity.

Frame of cooling towers is usually manufactured from steel with a corrosion-resistant coating, or from steel hot-dip galvanizing, at least from the in-situ concrete and profiled GRP profile.

Fans have impeller diameters from 2500 to 10400 mm depending on section size and performance of the cooling tower. Impellers can have from 3 to 8 blades are made of fiberglass, making them light weight and reduces the load on the actuator.

The fan stacks is made of composite materials reinforced with fiberglass. The special design of the fins on the external surface of the housing ensures its rigidity. The technology, based on the double wall allows to keep a smooth surface both inside and outside of the diffuser. Lightweight portable panel construction reduces the cost of transportation and facilitates the installation. High precision manufacturing of each segment provides a gap between the fan impeller and the wall of the housing in the plane of rotation is 3-4 cm. The housing is provided with rigid mounts to reduce vibration and to compensate the influence of running of the fan.

The fan drive can be either coaxial (inside the diffuser) and external (external gear drive).

|

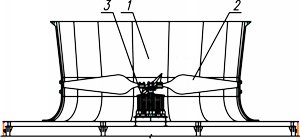

Schematic diagram of the coaxial drive.

1. The fan casing

2. Impeller

3. The motor

|

|

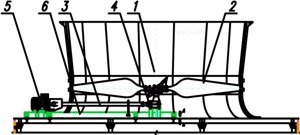

Schematic diagram of the remote (gear) drive.

1. The fan stack

2. Impeller

3. Shaft made of composite materials

4. Reducer of special design

5. The motor

6. Base frame drive

|

The external drive consists of a motor placed outside the fan stack on the frame, a shaft made of composite materials, transmitting torque, and gear, placed directly in the area of the cooling tower above the water distribution system on a support structure. The impeller is mounted on the vertical shaft of the gearbox.

Spray nozzle is one of the main structural elements of the cooling tower, defining its cooling ability. The sprinkler design must provide sufficient surface area to cool with optimal aerodynamic resistance. Depending on the nature of the dominant surface cooling sprinklers are divided into: film, drip (drip-film), combined.

The water treatment is designed to bring the chemical composition of recycled water in accordance with the technical norms for the correct operation of cooling towers and technological equipment of water circulation circuit. Significant loss of water by evaporation, particularly in summer operation, cooling towers – up to 3% per hour increase in circulating water concentration of hardness salts. Salt deposits adversely affect the distribution system, the corrosivity of the coolant also increases. Effective solution of this problem are demineralisers installation on ion-exchange resins and anticorrosive agents. To prevent the growth of biological microorganisms, the system adds the chemicals-biocides. Given the high costs of water in cooling towers of sectional type, the water treatment system typically are placed in a separate specially equipped room. Also produced mechanical water filtration from the insoluble substances.

Cooling tower can be equipped with a control system for trouble-free, economical and efficient operation.

Main technical characteristics of section mechanical-draft cooling tower

|

Parameter |

The value |

|

Volume flow, m3/h |

32 - 6000 |

|

Heat load, MWt |

0,4 - 83,8 |

|

The size of the cell, m2 |

4х4 - 18х18 |

|

t max inlet water, оС |

35 - 37 |

|

t min cooled water, оС |

23 - 25 |

|

The diameter of the fan, mm |

2500 - 10500 |

|

Drive type |

coaxial / geared |

|

Power used drives, Wt |

11 - 250 |

Developed and used our solutions for fan cooling towers provide high temperature extremes, reduce energy consumption up to 50% guaranteed and provide cooling water for the production process.

Technologies

In frame kit includes grounds maintenance of equipment security fencing and railings, supports for lighting.

|

|

|

|

|

|

|

|

Impeller stamps WTR© fiberglass may have a diameter of up to 20000 mm and the number of blades from 3 to 8 are made of fiberglass. Depending on the desired operating parameters of the cooling tower (flow, static pressure, noise characteristics) is possible to use 5 different variants of the profile of the impeller.

|

Тype: 1

Material: fiberglass

The linear velocity of the end of the blade: max 81 m/c

The angle of attack of the blade: 1-28o

The number of blades in the impeller: 3-8 PCs.

Wheel diameter: 4500-8000 mm

|

This type belongs to a class of versatile, high-speed, high-performance profiles. In the range of linear velocities of the end of the blade 61-81 m/c this profile provides maximum performance and low power dissipation level of noise. Used as a replacement for old worn out wheels on an existing enterprise without replacing the drive system (motor, reducer, drive shaft). Thanks to its versatility, the blade has been used very successfully in new projects.

|

Тype: 2

Material: fiberglass

The linear velocity of the end of the blade: max 77 m/c

The angle of attack of the blade: 1-28o

The number of blades in the impeller: 3-8 PCs.

Wheel diameter: mm 1200-20000

|

This type belongs to a class of versatile, high-speed, high-performance profiles. The geometry of the blade allows to ensure the declared characteristics of the flow rate and static pressure with a small number of them (usually 4-5 pieces), which makes the impeller is cost-effective. This option is ideal for replacing old worn wheels on an existing enterprise without replacing the drive system (motor, reducer, drive shaft). Thanks to its versatility, the blade has been used very successfully in new projects. Profile allows to achieve good power dissipation figures for the noise – to 75-80 DB.

|

Тype: 3

Material: fiberglass

The linear velocity of the end of the blade: 62 max m/c

The angle of attack of the blade: 1-28o

The number of blades in the impeller: 3-8 PCs.

Wheel diameter: mm 1200-20000

|

This type belongs to a class of special, low-speed, high-performance profiles. Complex geometry with a large surface area provides maximum performance in average static pressures up to 130-140 PA at low speeds 90-110 rpm Usually applied in systems where attention is paid to the power dissipation of the noise. Power noise can reduce to 60-65 DB.

|

Тype: 4

Material: fiberglass

The linear velocity of the end of the blade: max 95 m/c

The angle of attack of the blade: 1-28o

The number of blades in the impeller: 3-8 PCs.

Wheel diameter: mm 1200-10400

|

This type belongs to a class of versatile, high-speed, high-performance profiles. The profile is designed to provide high pressure with a high flow pump air masses due to the higher speeds of rotation of the impeller to 175 rpm (when the diameter of the wheel 10400 mm). This profile is the most productive of the entire line of AKVANN. The number of blades in the impeller for the standard cooling towers usually no more than 4-5 pieces, and, therefore, makes a wheel attractive from the economic point of view. Is used for replacing the old impeller and new construction.

|

Тип: 5

Material: fiberglass

The linear velocity of the end of the blade: max 51 m/c

The angle of attack of the blade: 4-32o

The number of blades in the impeller: 3-8 PCs.

Wheel diameter: 800-6000 mm

|

This type belongs to a class of special, low-speed, high-performance profiles. A profile is a response to the change of world trends towards silent fans with low rotation speed. The profile is primarily designed for use in systems where the dissipation factor of the noise plays a primary role. Without additional measures of noise reduction, it is possible to reduce the power dissipation of noise to a value of 55-60 DB. Fan installation with this profile can be used in residential areas, on the roofs of buildings in the city.

The impeller blades and the edge covered with anticorrosive compositions, resistant to corrosive environment in the cooling tower. The linear speed of the end blades more than 61 m/c, the front edge is additionally protected by an aluminum plate. Special purpose blades may be manufactured in the following versions: antistatic, antacid/protivosokowoe, self-extinguishing, high temperature/low temperature.

The electric motor drive in the case of using the remote actuator is located outside the cooling tower. In the coaxial embodiment, the electric motor is located directly in the zone of the cooling tower. Motor equipped with Parking brake, so that no reverse rotation during stop and simplifies the maintenance of both the engine and the cooling tower as a whole. To protect from overheating, the basic equipment of the engine includes sensors for monitoring temperature of stator winding and bearing nodes. If necessary, can be made explosion-proof certificate is provided under international explosion safety category ATEX.

Reducer (in case of a remote drive) is specially designed for cooling towers subject to high axial loads, motor loads, aggressive environments. It's possible to set the reducer heating elements, for heating oil with the purpose of easy start in the winter, and a sensor system for the control and safe operation of the gear (sensors: temperature, vibration, oil flow, oil pressure, the presence of impurities in oil...). As a protective measure provided a system of mechanical filtration of the oil. To facilitate servicing flood/drain oil lines are removed from the immediate areas of operation of the gearbox. Corrosion resistance the casing is provided with special coatings, the composition and number of layers which are determined by the parameters of the working environment. To prevent overcooling of the coolant in winter operation in reverse gear is provided for pumping warm air back into the zone of the cooling tower. If required, the gearboxes are provided with the certificate of explosion safety in the international category ATEX.

The shaft of the top drive is made of carbon fiber, equipped with a flexible coupling and is capable of withstanding high peak loads and to transfer high torque. It has extremely low weight, allowing easy installation. The shaft is dynamically balanced to class G6.3 according to GOST ISO 1940-1-2007. If necessary, shafts are given the certificate of explosion safety in the international category ATEX.

The fan drive in the basic version is equipped with an integrated control system of the frequency Converter that is controlled according to the water temperature sensor at the outlet of the cooling tower. The frequency Converter allows to eliminate unwanted mechanical starting load on the drive and the grid, and also provides significant energy savings during the autumn-spring period of operation of the cooling tower (30-50%). Alternatively, the variable frequency drive possible less flexible the option of using the soft starter (soft starter) or fluid couplings.

Water distribution system in the basic version is made of fiberglass pipes. The variant with the main reservoir of FRP and peripheral collectors of PVC or water distribution system of steel with corrosion-resistant coating.

Wide application of components of cooling towers made of fiberglass, allows to prolong their life and corrosion more than twice, increase overhaul interval, reduce operating costs of the service and accordingly get the savings.

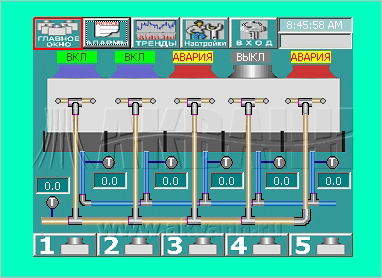

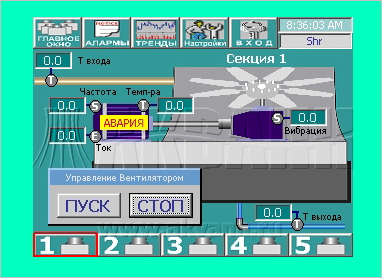

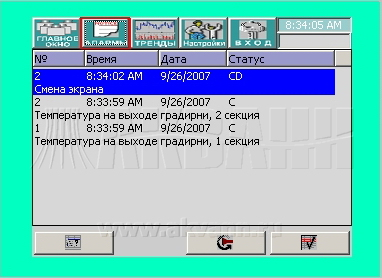

Automation

Control system basic version includes monitoring of the following parameters: the temperature of inlet and outlet water, ambient air temperature, the vibration of the actuator Assembly, temperature and oil pressure in the gearbox, the temperature of bearings and windings of the motor, flow rate, liquid level in a collecting tank.

During the winter start-up is carried out by preheating the oil in the gear casing when the stop motor is enabled protivokongestevnoe heated. To prevent the autorotation of the blades of the impeller, the system activates the electric Parking brake. In order to avoid overcooling of the coolant in the circuit (the defrost system) is provided for reversing the rotation of the blades of the fan impeller.

Emergency stop actuator provided local push button stations.

If necessary, the local process control system may also control the pump station, carrying out, including frequency regulation, control of dry start-up pressure, overheating of the bearing assemblies of the pump motor.

Available integration of local APCS in the complex treatment system of the enterprise protocols of Ethernet or RS-485/422/232, saving data on the drive, remote control and management system.